Flame Treatment

RLS Flame Treatment Systems

Are you losing customers due to poor adhesion? RLS Flame Treating systems provide reliable, repeatable, surface treatment on your substrate for maximum adhesion. We can help you get high dyne levels and the perfect air to gas ratio for superior printing and gluing application results. Safe and effective for plastic, metal, glass bottles, containers, molded parts, interior automotive parts, sheets, gaskets, tubing, wire, virtually any substrate that needs quality adhesion results.

Other popular applications include – Parting line removal, removing flash or “angel hair” from molded plastic products, or applying heat for your manufacturing process.

Do you need to

improve your product quality with better adhesion?

- Increase durability

- Dyne levels of 70 or higher

- Better adhesion of inks, glues, dyes, paints, and coatings

Advantages over Corona / Air Plasma Treatment

- Higher achievable treatment levels

- Lower treatment decay rates

- No backside treatment

- No ozone

- No gauge or surface contour restrictions

Advantages over Chemical Treatment

- Chemical treating creates odor

- No skin irritation

- Less expensive

- Does not require disposing of environmentally hazardous material

- Chemicals expose workers to dangerous substances

Robotic Cell

- Robot contours the part with the flame.

- Increases surface tension of the part.

- Enhances adhesion of substrate to the surface.

- Substrates include printing, painting or gluing.

- Flame Surface Trimming ‘smooths’ the surface of parting lines.

Round Plastic Bottle Flame Treater

- Flame treat multiple sizes of plastic round bottles.

- Accomadate multple neck finishes of differet sizes.

- Run up to 30 containers per minute.

High Speed Bottle Flame Treater

- One of the most versatile flame treaters on the market.

- Increase the surface tension and dyne level.

- Treat both plastic and glass bottles.

- Extremely adjustable turner treats opposite sides and quadrants for round bottles.

- Speeds can be set to match your upstream or downstream equipment.

Large Sheet Flame Treater

- The most popular sheet flame treater on the market.

- Treat large plastic sheets, aluminum sheets, door panels.

- Handles flats up to 6 feet wide by 15 feet long.

- Dyne levels upwards of 70 dyne.

- Sensors ensure flame is lit and fault for improper height settings.

Flame Panels

- So versatile it can be used for many applications for plastics, glass, printing, and gluing.

- Specify the number of burners, the length of the burners, and what type of controls work best.

- Mounted anywhere including: existing conveyors, robot heads, servo and linear guides.

- Controlled via upstream or downstream PLCs.

- Run on natural gas or propane, and have the highest safety standard controls in the industry.

“Gallon” Flame Treater

- Most accurate ways to flame treat gallon bottles.

- Treats by stop and spin in front of the flame.

- Flexibility to be fitted with a flame bypass to conserve energy when running batches of bottles that do not need treatment.

- Extremely repeatable with speeds of 30-60 per minute.

- Expanded to treat shorter jugs, pails, flower pots, canisters, and other large symmetrical round objects.

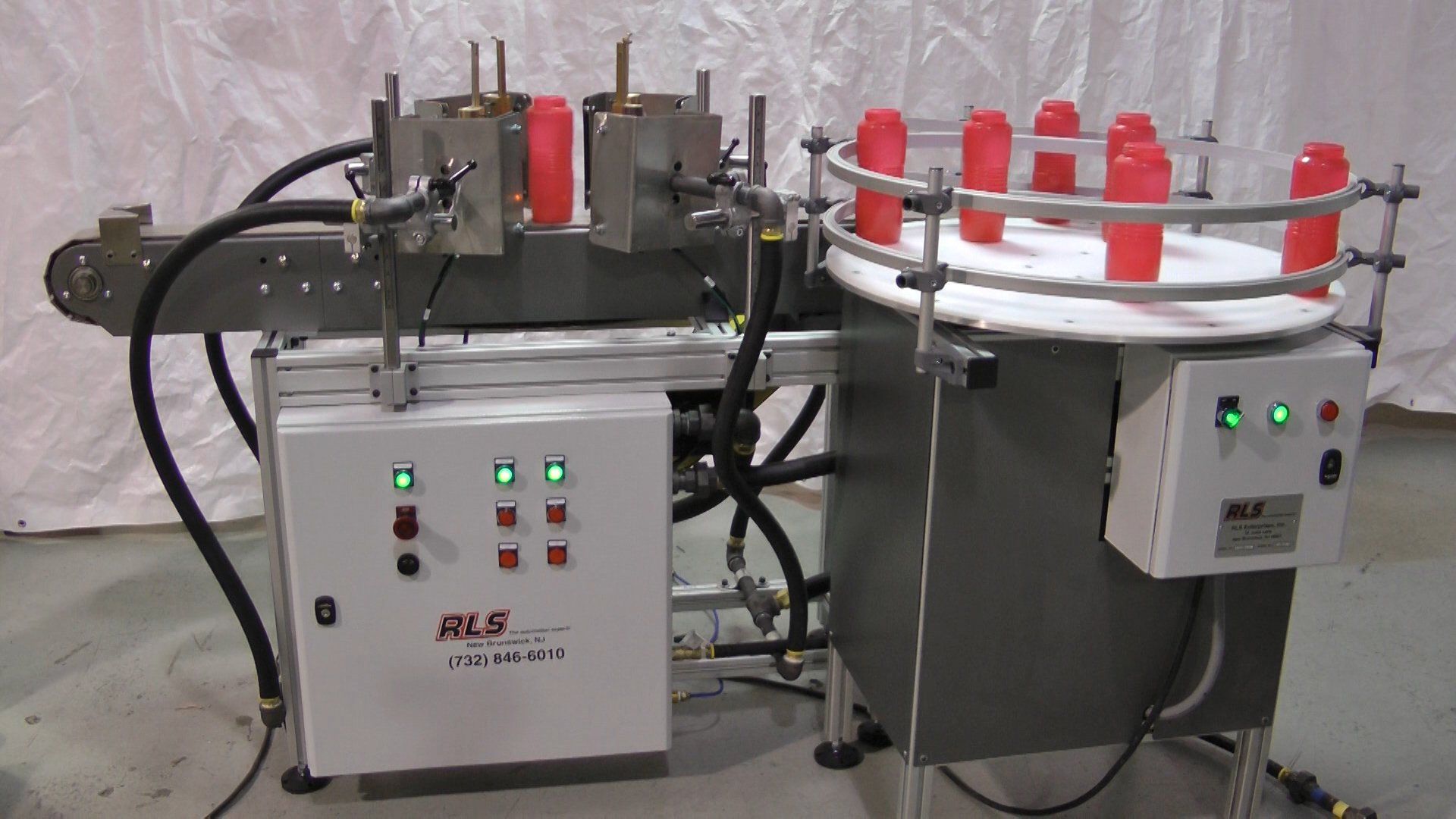

Four Burner Quadrant

Flame Treater

- Adjustable burners for various size bottle or containers

- Independent mixing systems on each pair of burners, only one set can be used for flat or ovals

- First set of angled burners will treat the back quadrants of round bottles, while the second set of angled burners will treat the two front quadrants

- Conveyor and optional accumulation table provide a great turnkey solution

Drop Flame Treater

- Easy to use, durable stand-alone system.

- Increases surface tension on plastic bottles, plastic parts, plastic novelties, etc.

- Burners pivot with chute to vary part speed.

- Hand-fed unit but automatic feeder is optional.

- Available in two high level performance systems.

Ring Burner System

- Gravity-free drop through flaming

- Mountable to existing plastic extrusion line.

- Unique feature keeps product dropping through the center of the ring at all times.

Ribbon Burner System

- Increased adjustability for wider parts.

- Top and bottom sheet treating simultaneously.

- Perfect for plastic novelty items, mugs, short tubes, medical products, and even square bottles.

Portable Existing Conveyor Flame Treater

- Versatile applications in the plastics, glass, printing, and gluing

- Specify the number of burners, the length of the burners, and what type of controls work best.

- Mount over existing conveyors, or move from production line to production line.

- Built in burner guarding makes this a complete turnkey machine.

- Controlled via upstream or downstream PLCs.