Pyrosil Treatment

RLS Pyrosil and Silicating FlameTreatment Systems

Pyrosil is a proprietary flame technology which has a 40+ year track record of success in adhesion promotion and durabality for countless materials and substrates. Automotive glass, Sheet Glass, aluminum, and solar industries all benefit from the competitive advantages that manufacturers gain with Pyrosil treatment.It is the leading pretreatment solution for glass decorators dealing with cold end coated glass. Small glass bottles, perfume bottles, candles, wine bottles, craft beer bottles, and liquor bottles are all pretreated with Pyrosil prior to UV ink printing. RLS offers test equipment and Pyrosil dosing units onsite for testing. We also offer rentable hand held units for testing in your facility. To learn more about Pyrosil and its many benefits, take a look at our videos below and our whitepaper presentation.

Are you still using a

Lehr? Or wiping your

substrates with hazardous chemicals??

- Made in the USA and available at a fraction of the cost of comparable European equipment

- 360 degree treatment without turning the bottles, even on half gallon growlers

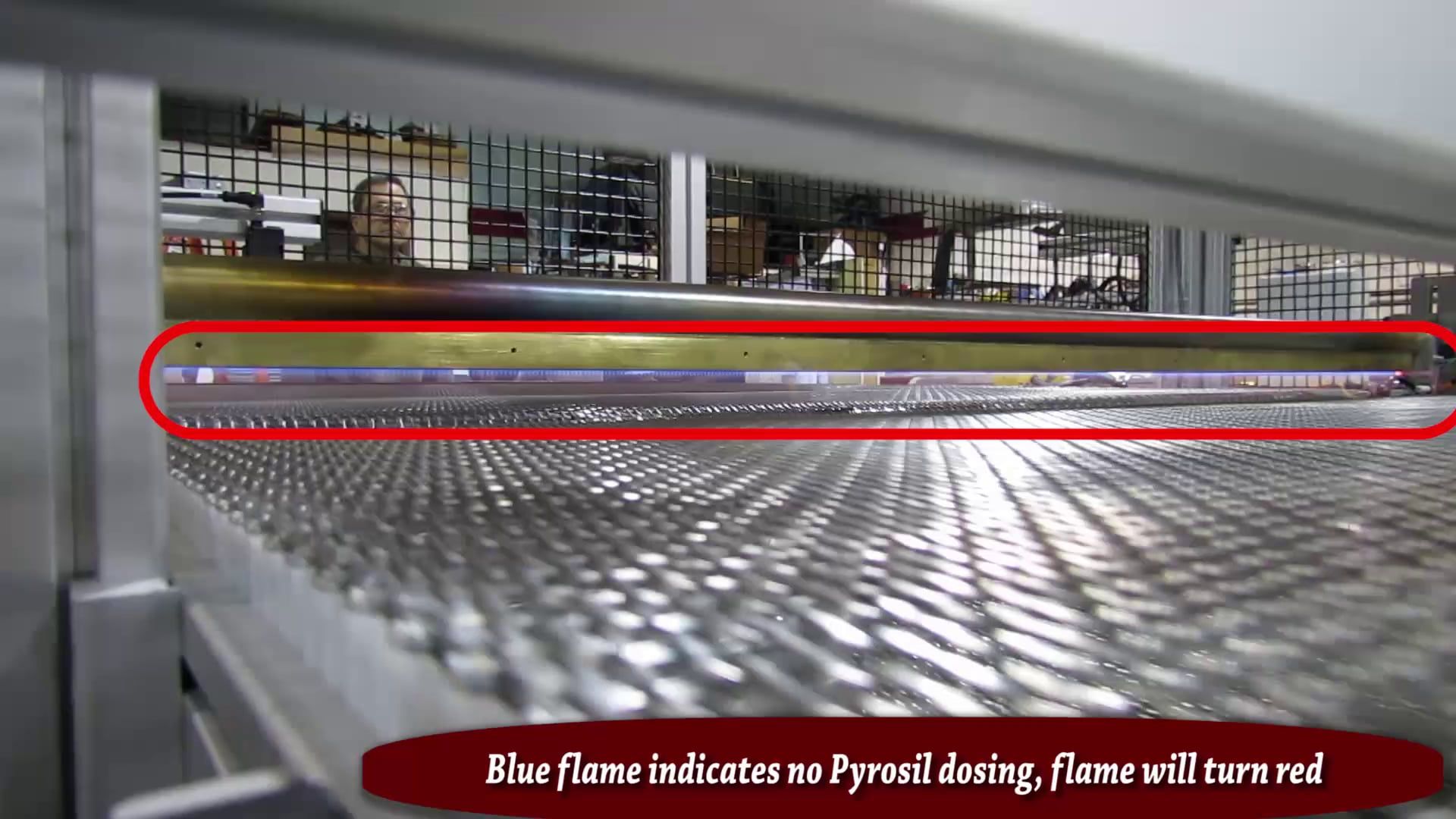

- A touch of a button, you have automatic ignition, continuous flame monitoring, and the proper dosing of Pyrosil into your flame

- Preferred pretreatment for organic UV inks and environmentally responsible manufacturers and decorators

- Adjustable burners and guide rails run wine bottles, beer bottles, pint glasses, growlers, wineglasses, and virtually any other glass beverage container

- Cutting edge equipment available for precise measured dosing of vaporized liquid vs. estimated deposition

Hand Held Unit for Research and Development

- Uses premixed cartridges

- Testing can be done right in your facility

- Easy to apply to any substrate

- Automatic ignition handles available on applicator wand

- Low cost R&D to test the process and technology

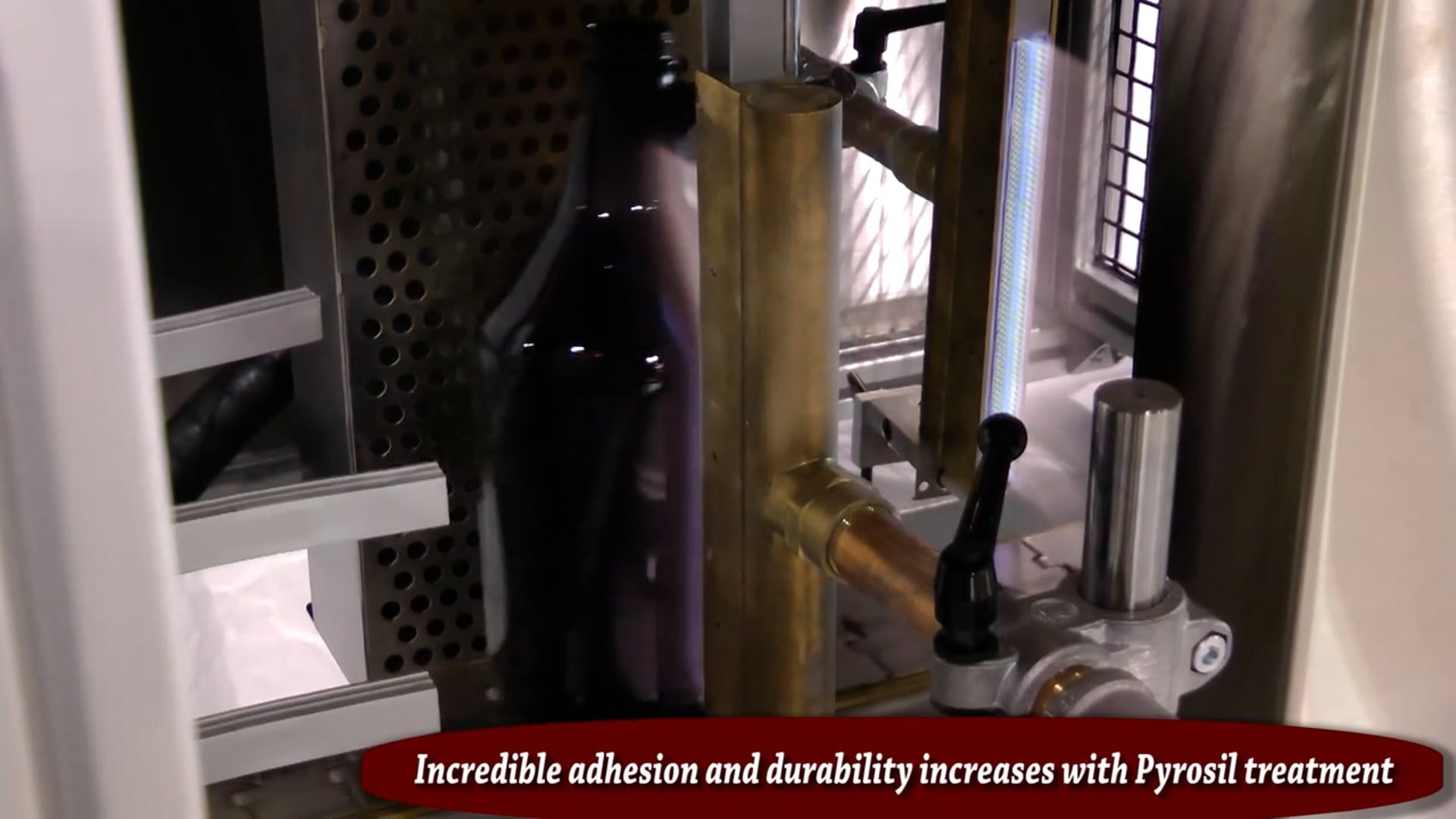

Single Station Unit

- Up to 12 containers per minute

- Index, Dwell, Rotation all adjustable via the HMI

Quick change tooling for different diameter or shaped containers - Flame Safeties, rectification, and operator foot pedal

Production Pyrosil Flame Treaters

- Layouts designed to fit your production needs

- Optional pre-flame and oscillating burners

- Only US manufacturer to build to NFPA standards

- Please excuse shakiness in some videos, they are taken from factory acceptance tests

Sheet Pyrosil Flame Treaters

- Used for aluminum, glass, layered laminates, smart boards, automotive, printing, flooring

- Can be built for an array of thicknesses, widths, and lengths•Automate directly into printer or other downstream equipment