Line Integration

Line Integration

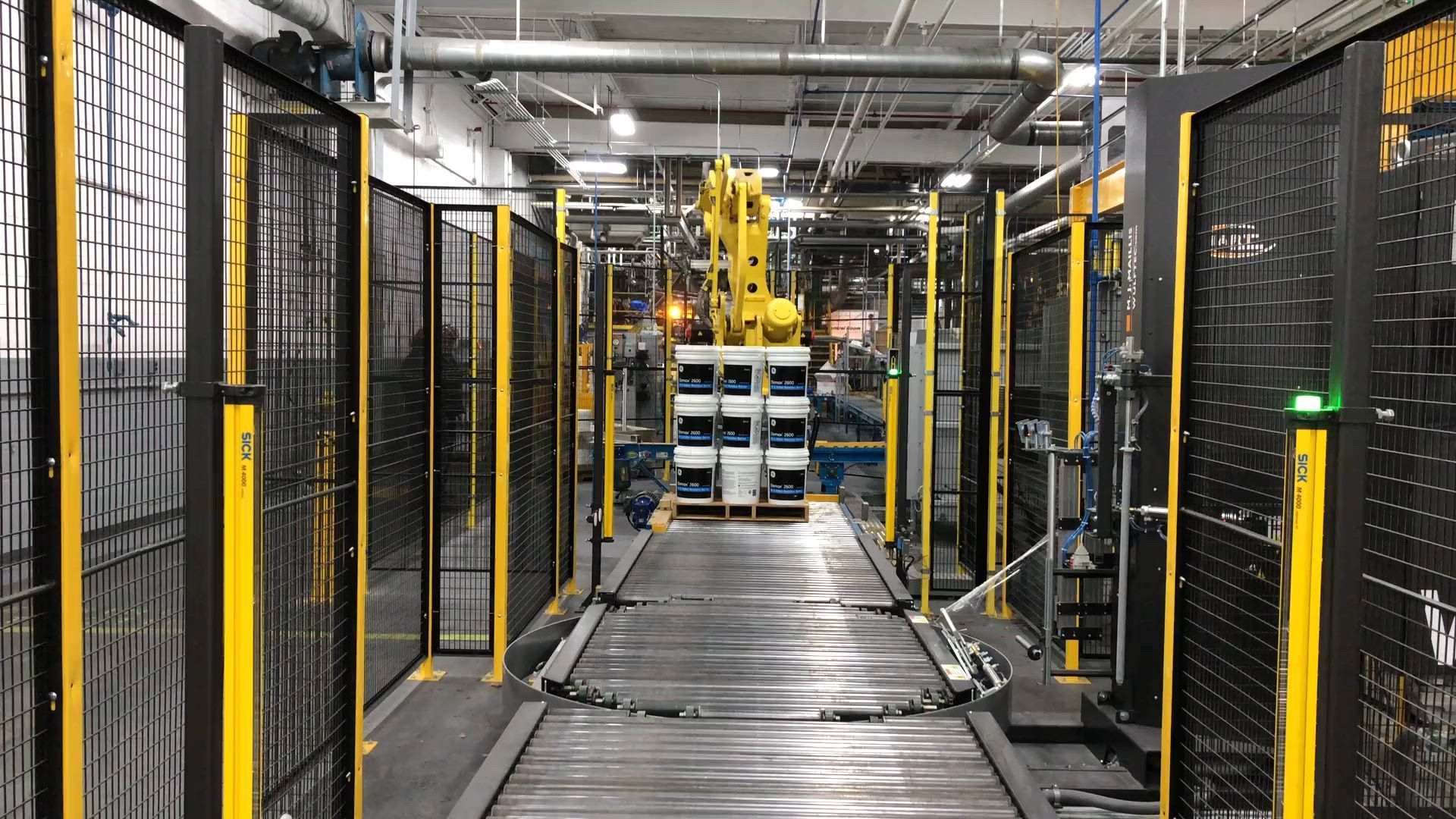

When the term “Turnkey Automation Solution” is being used, RLS completely understands this term and what the responsibilities are to provide a successful Turnkey project. All aspects of the project must be reviewed and analyzed that the proper equipment selected for each phase of the job. RLS works closely with the customer acquiring their knowledge of their product and past equipment used by the plant that was successful.

Hazardous locations often present difficult problems. RLS has installed complete packaging lines in Class I Division I areas. Understanding the scope of work is key to acquiring the correct and safe equipment for the project.

Fillers, cappers, conveyor systems, part feeders, lid feeders, bar code readers, camera systems, labelers, depucking systems, robotic pick and place, case packers, case erectors, case tapers, palletizing systems and stretch wrappers are some of the equipment RLS can provide for your turnkey solution.