Pick And Place Systems

Pick and Place Systems

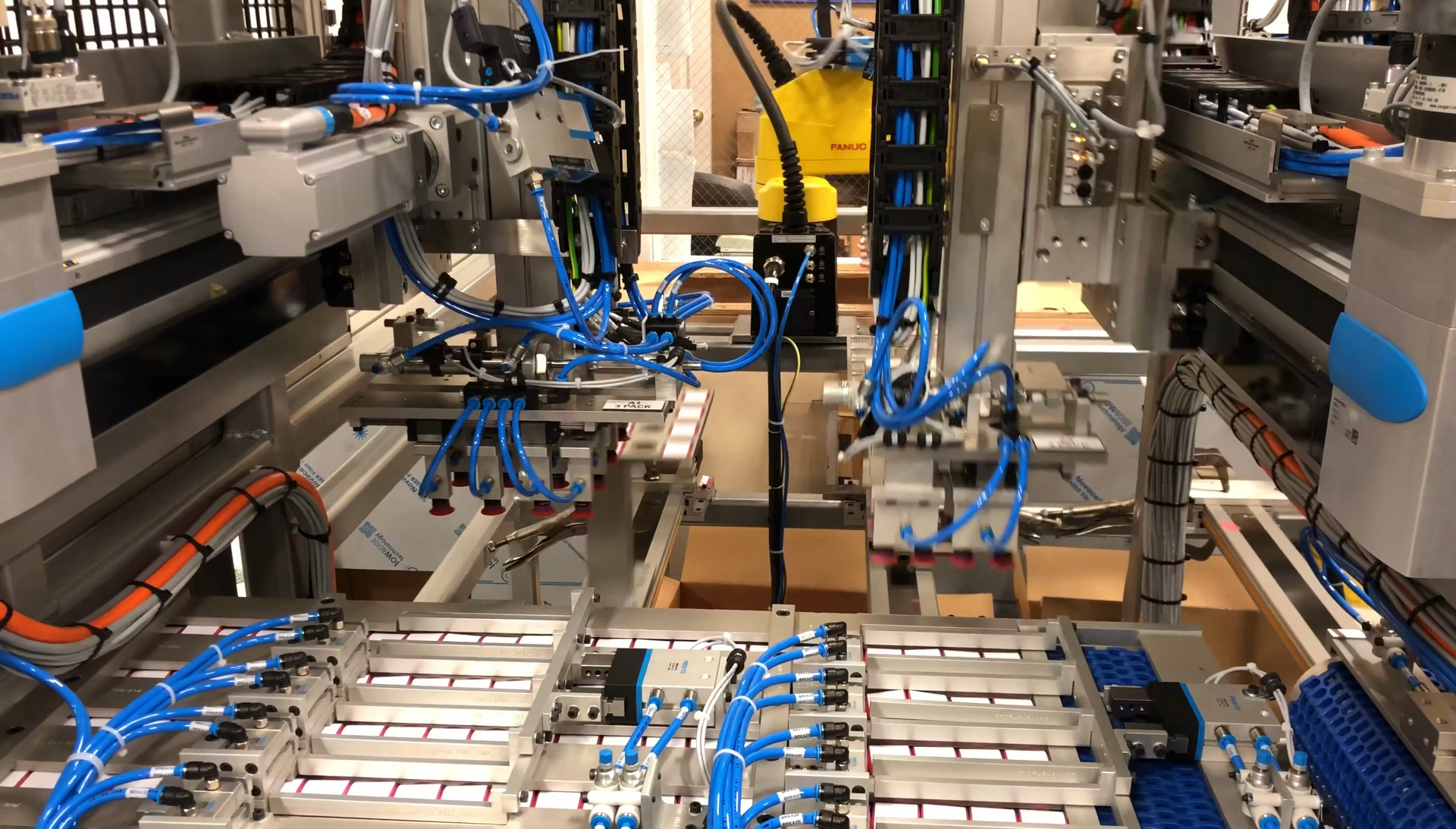

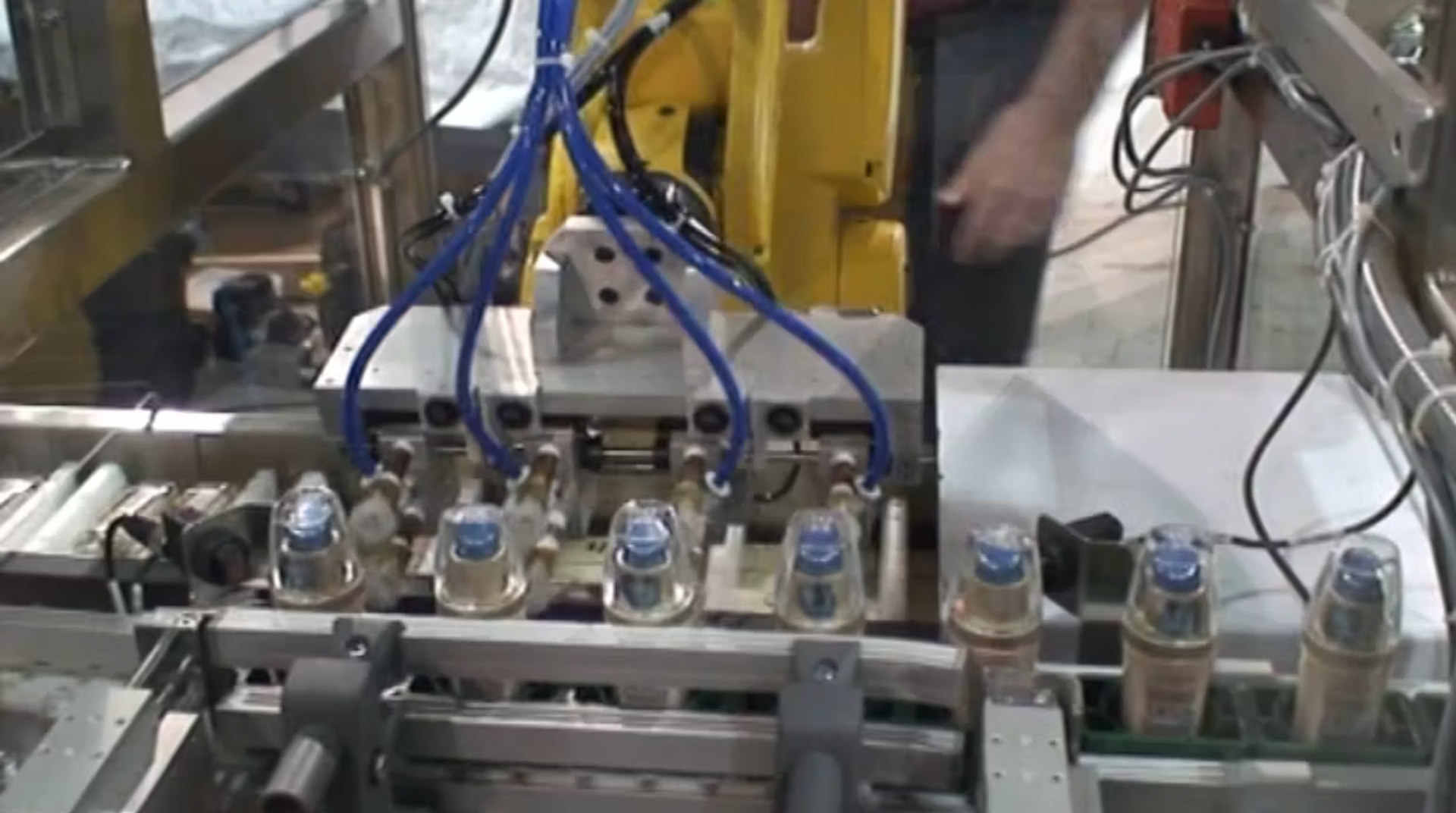

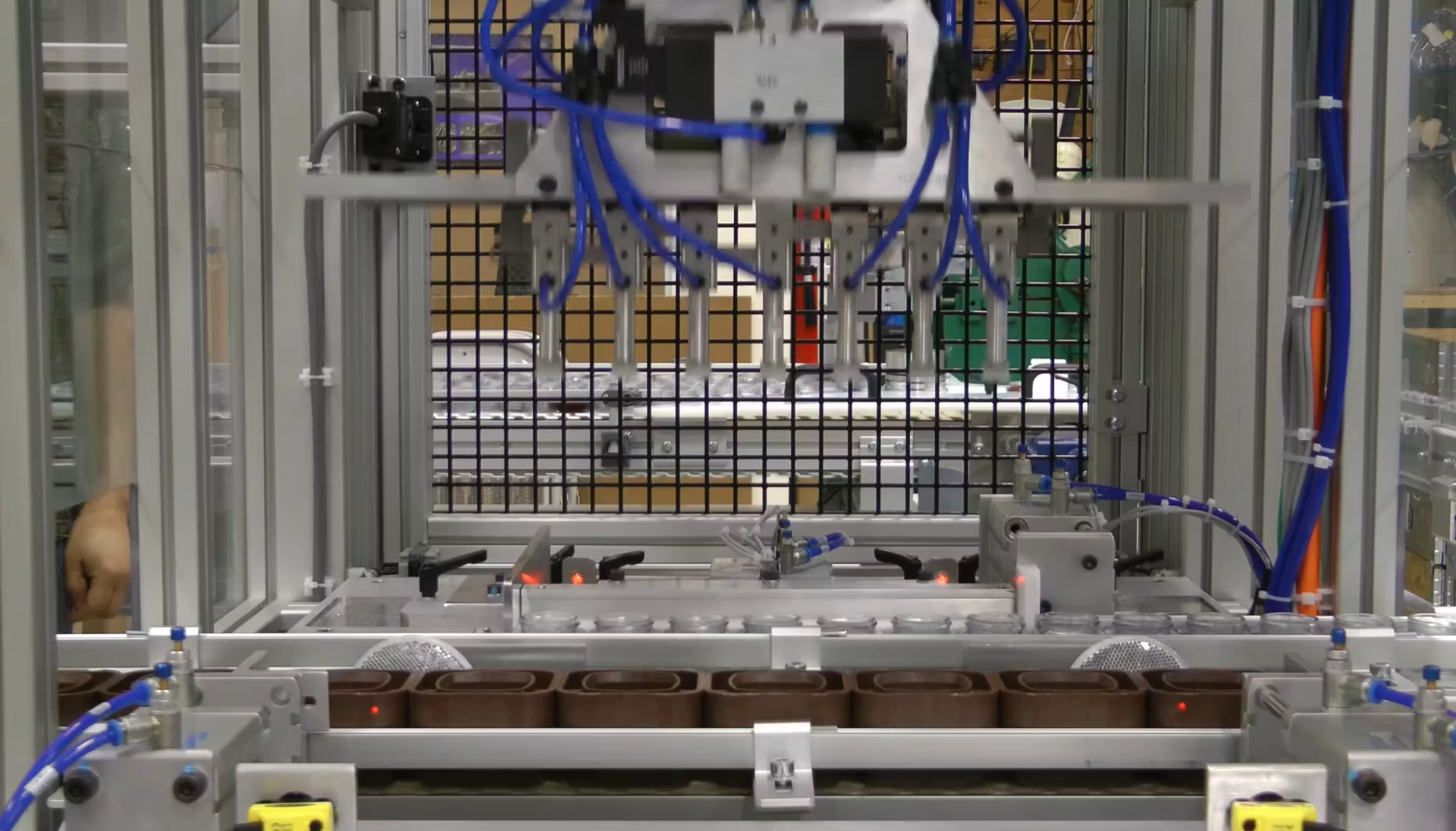

The art of knowing which type of robotic system to successfully accomplish the goal of the customer is a specialty of RLS. Our many years of experience provides a large background of past projects to pull from for ideas and concepts. There are many types of pick and places systems available in todays automation: Articulated arm, high speed Delta robots, scara robots, parallel linkage arms, servo and pneumatic cartesian system.

Product weight, required speeds, reach and budget are key factors that go into the selection of the style of pick and place automation that will be used.

RLS will carefully evaluate all aspects of the project with the customer to determine the right choice to guarantee a successful project.